Strength

Products

Ultra Thin Metal Foil with Plating

Cutting edge plating thin metals of roll to roll type for smart phone, LCD, OLED, PTC, EMI, RFID, battery, fine pattern printed circuit, steel pipe and so on.

- Description

-

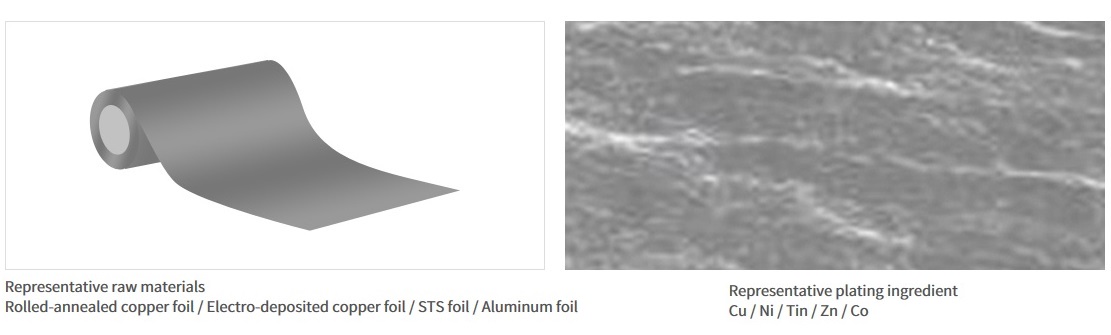

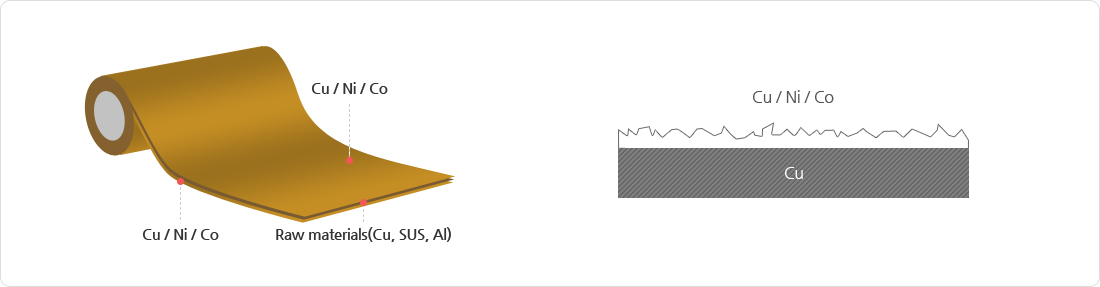

To give the physical and chemical properties demanded by customers to metal foils used in electric and electronic products, we are plating mono metal or two or more types of metals and electronically plating alloys of various thicknesses in 0.1-5㎛ to 10-300㎛ thickness metal foils in continuous processing lines. Also, our nodular treatment technology has advantages of reinforcing the adhesion with polymer based on the size and shape of metallic nano powder and improving the electric property.

Feature

Roll to roll Type

Roll Width : +1700 Speed : Max. 100m/min

Coating method : Gravure, Micro Gravure, Comma ( 3 types )

Dryer : 4m x 5 zone ( Max. Pemp 180°C

Specification

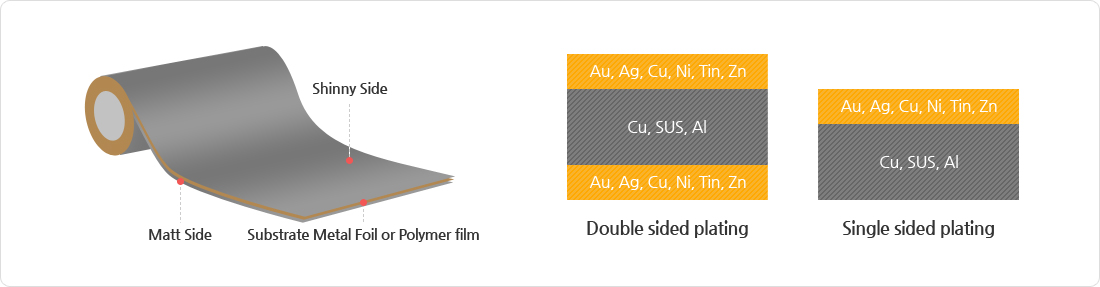

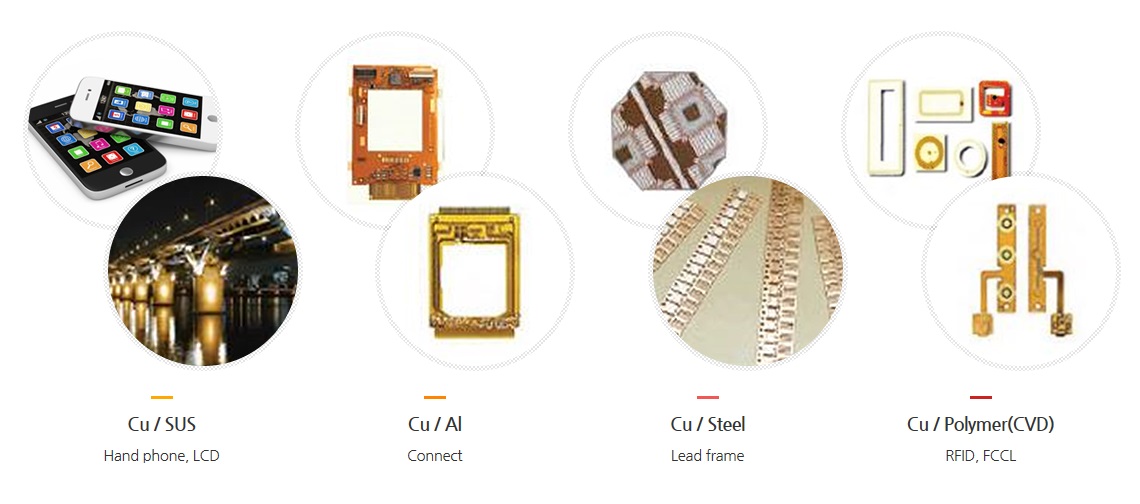

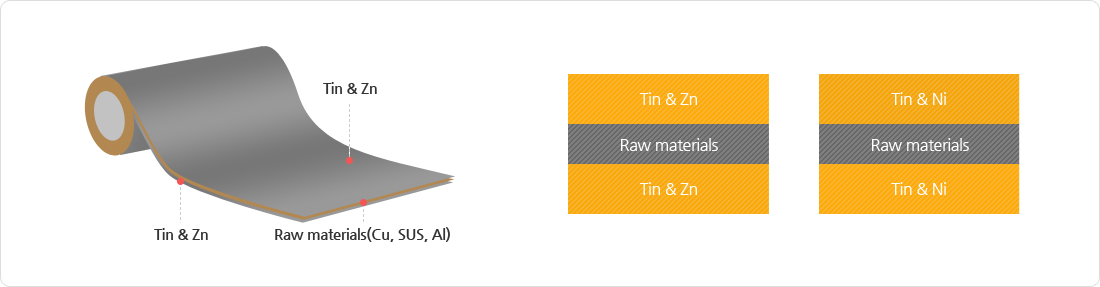

Surface treatment can be done on double or single sides, and plating is performed on various raw materials using different ingredients.

Products made from this process can substitute expensive metals or rare metals, be given electromagnetic properties, and prevent corrosion of product.

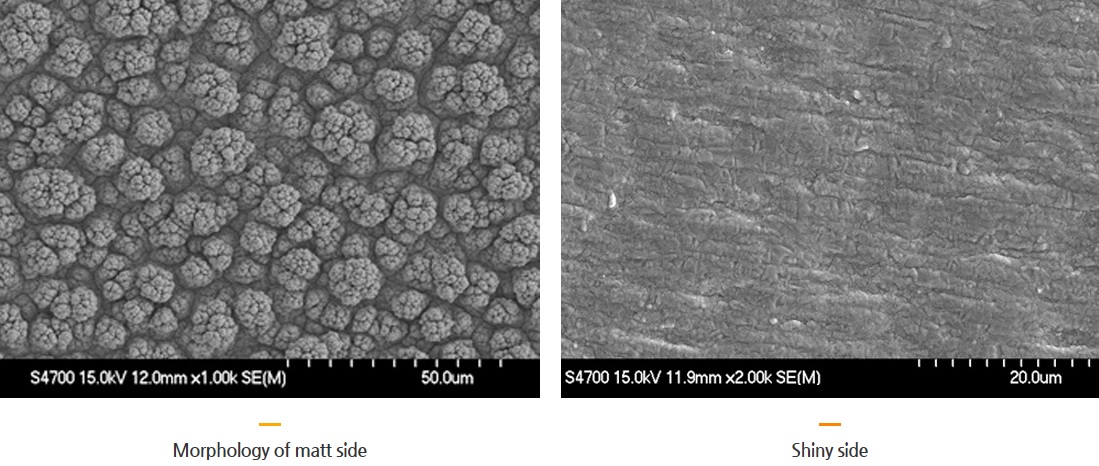

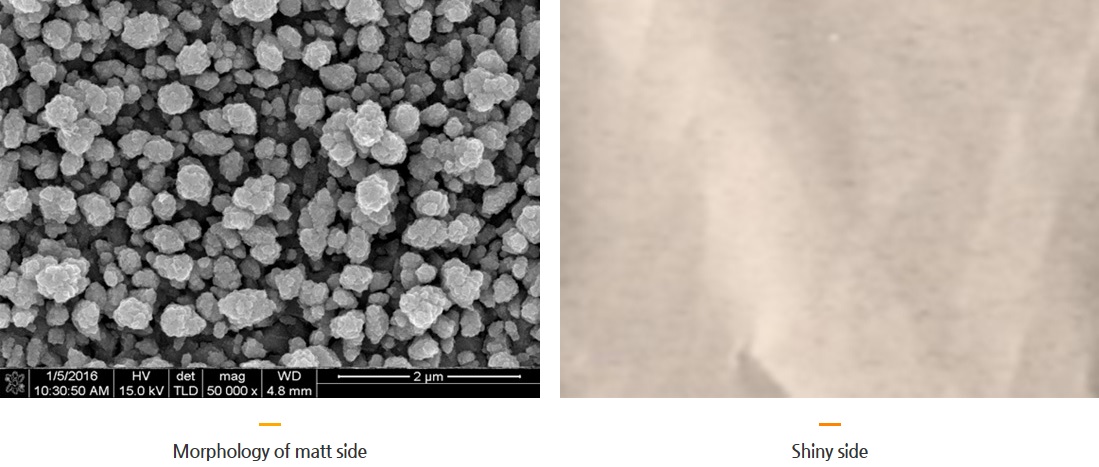

Also, each side is differently plated. In particular, the shiny side and matte side show unique appearances.

Of the above, matte side is produced by applying metallic nodular technology in nano size to maximize adhesion with polymer (PE, PI, PET), and the opposite side is plated in uniform and clean appearance of final product..jpg)

Product, Examples of Plating

Plating surface image

Single plating applications

Alloy Plating

For example, binary alloy plating such as tin and tin/zinc has good elongation property and increases lubrication and abrasion resistance, hence providing an important role of increasing dip drawing and plastic forming property during plating on general steel.

For example, binary alloy plating such as tin and tin/zinc has good elongation property and increases lubrication and abrasion resistance, hence providing an important role of increasing dip drawing and plastic forming property during plating on general steel.

We can supply multiple alloy foils in thicknesses from hundreds of nano meters to tens of micrometers onto various thin foils (copper foil or various films according to the composition and conditions demanded by customers.

Product example

Binary alloy

Ternary alloy

Plating surface image

Multiple plating application area

Black Plating

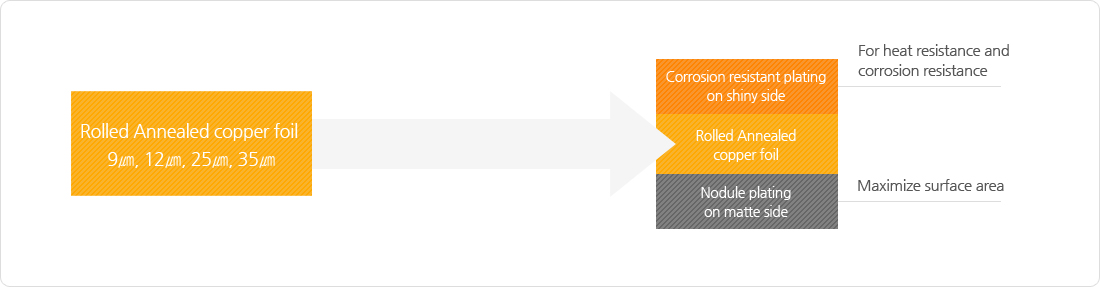

- Developed nodule plating technology and corrosion resistant plating technology using rolled copper foil

- Nodule is formed on the matte side, maximizing the surface area for higher adhesion strength whereas the shiny side is plated for heat resistance and corrosion resistance

Characteristics of plated foil

- Maximized adhesion strength through hundreds of nano sized micro nodules

- Superior heat resistance property through increasing surface area

- Corrosion resistance and heat resistance of product through post-process plating

Surface color

Our product

| Company A

| Company B

| |

|---|---|---|---|

| Color | Yellow | Pale yellow | Redish |

| S-side |  |  |  |

| M-side |  |  |  |

| Color | Dark-black | Red-black | Dark-black |

Microscopic Images

| Our produt | Company A | Company B | |

|---|---|---|---|

| S-side (x30) |  |  |  |

| M-side (x200) |  |  |  |

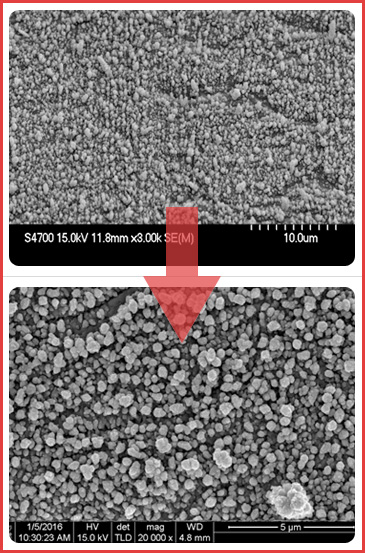

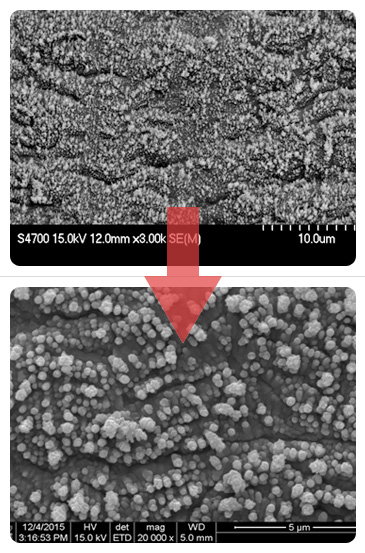

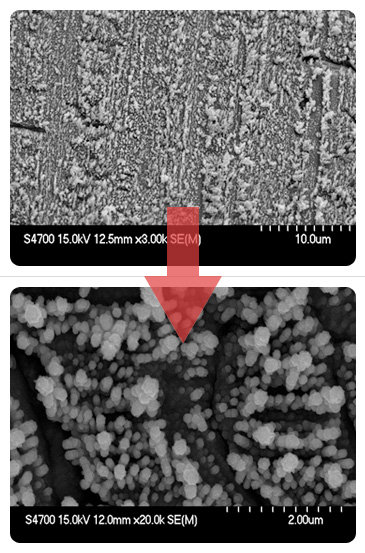

SEM Image of M-Side

| Our product | Company A | Company B |

|---|---|---|

|  |  |

Our nodules are more densely formed for increased adhesion strength. (Number of nodules/ μ㎡: Our product > Company A > Company B)

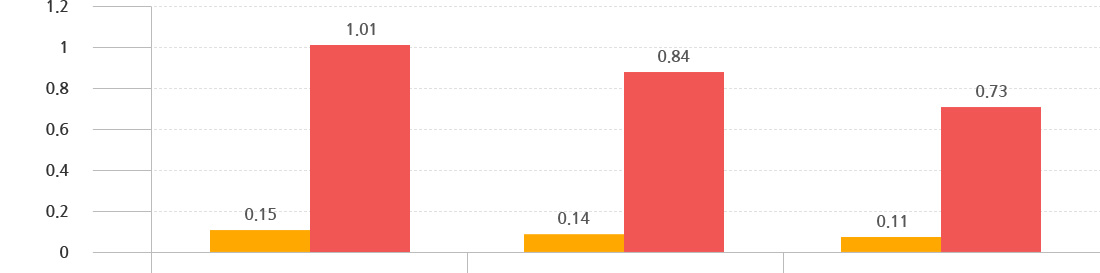

Roughness

- Ra

- Rz

| Our product | Company A | Company B | |

|---|---|---|---|

|

|

|

Our product |

Company A |

Company B |

|

|

|

Material

thickness |

35㎛(25㎛) |

35㎛ |

|

|

|

|

S-side Ra |

0.14 |

0.11 |

0.11 |

|

|

|

Rz |

0.95 |

0.62 |

0.68 |

||

|

M-side Ra |

0.15 |

0.14 |

0.11 |

||

|

Rz |

1.01 |

0.84 |

0.73 |

||

We have maximized Rz to increase adhesion strength.

Thermo chromic Test Result (30 minutes at 200℃)

| Our product | Company A | Company B | |

|---|---|---|---|

| Before |  |  |  |

| After |  |  |  |

| Result | OK | OK | OK |

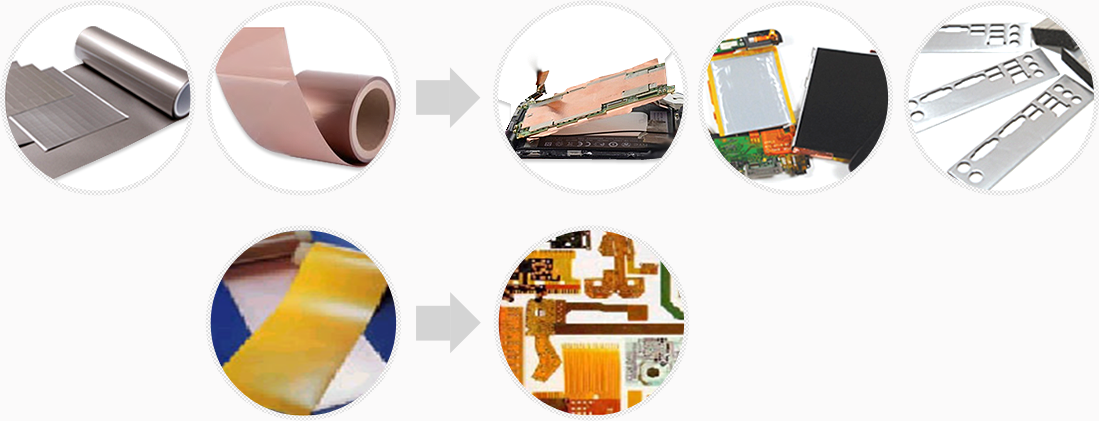

Application

Absorber(EMI shielding) · Thermal Spread Sheet · Conductive Tape · EMI Gasket · FCCL FCCL FPCB (FCCL+Cover lay)

![single_plated_img1[1].jpg](/upload/prod/single_plated_img1[1].jpg)